The term “prestressed concrete” (also known as pre-tensioned concrete) means that wet concrete is poured onto a steel strand which has been tensioned, after that concrete has reached the required strength that strand is de-tensioned, the cured concrete adheres and bonds to the strand and when the tension is released it is transferred to the concrete as compression by static friction. This gives the panels additional strength and enables them to flex under load without detriment.

In the past decades, prestressed concrete poles have become famous and have replaced the traditional poles made of timber, steel or reinforced concrete. The earliest prestressed concrete poles were designed in 1933 by Freyssinet, a French engineer.

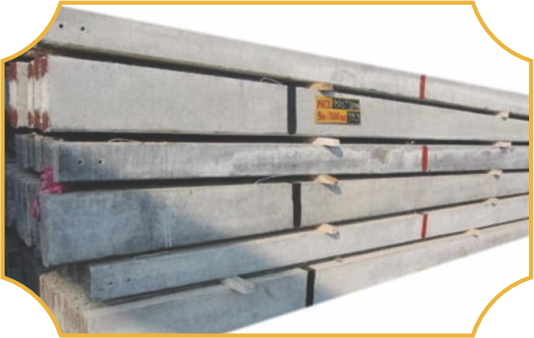

There are different shapes and cross-sections of prestressed concrete poles available but any type of pole, based should consist of a maximum cross-sectional area since it requires a maximum moment of resistance. Rectangular or square shapes poles are suitable for smaller lengths up to 40ft. They provide good facilitation for prestressed wires at the required depth. Transportation such poles are much easier.

Advantages

-

Less in weight and easy to handle.

-

Installation of prestressed concrete poles in drilled holes is easier and simple.

-

They are less permeable and provide good Resistance to corrosion of prestressing wire especially in hot weather regions.

-

Good Resistant to erosion in desert regions.

-

Good fire resistance is useful when bushfires or grassfires occur near the ground line.

-

Good resistance against freezing and thawing occurred in colder regions.

-

They have more rigidity and can carry higher loads than normal RCC poles.

-

They can be manufactured in a number of shapes with clean and neat finishing which makes them good in appearance.

Specification

8 Mtrs, 200 Kg (WL)

9 Mtrs, 200 Kg (WL)

8 Mtrs, 300 Kg (WL)